VITACO IS HOME TO LEADING HEALTH AND WELLNESS BRANDS

Vitaco is the home of Australia and New Zealand’s most trusted health food, sports nutrition and

supplements brands – Musashi, Aussie Bodies, Nutra-Life and Healtheries.

With a heritage dating back over 116 years, Vitaco’s vision is to Empower Healthier Lives in Australia, New Zealand and across the globe.

We win through our people

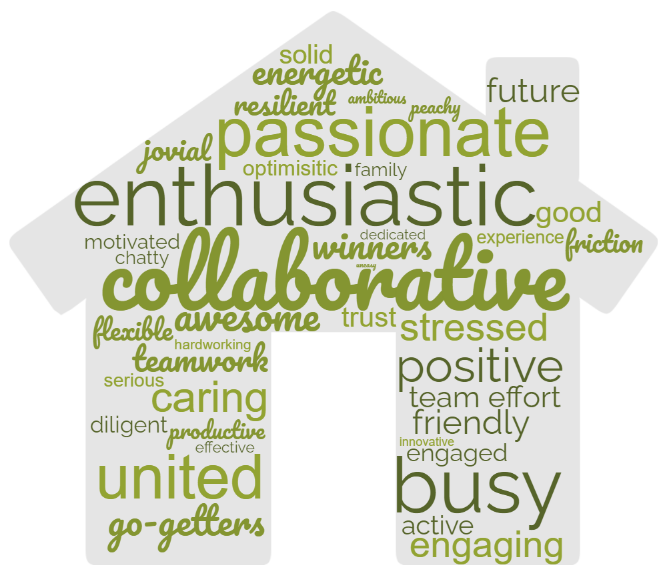

At the heart of our success are our people. We are proud of our diverse workplace, where everyone has the opportunity to learn, grow and contribute to our vision of Empowering Healthier Lives.

We Care, We Act and We Succeed.

Award winning brands

Driven by an obsession to innovate with scientifically supported and proven products, Vitaco is home to Australia and New Zealand’s most trusted health food, sports nutrition and supplements brands – Musashi, Healtheries, Nutra-Life and Aussie Bodies

World class production facilities

Our manufacturing facility in Auckland is renowned for producing a full spectrum of sport nutrition solutions, sourced from the highest quality ingredients.

Vitaco holds all required certifications and registrations required to produce a wide range of listed medicines, dietary supplement and foods.

Your trusted partner

We are proud of our Australia and New Zealand heritage, and equally proud of our vision to lead the world through our trusted partnerships in the Asia Pacific, Europe, USA and the Middle East.

Focus on sustainability

Our focus on sustainability means we are committed to taking bold action for a healthier environment. Together, we can each make a difference through leadership, transparency, re-imagining packaging, improved water and resource usage, minimising the impact of climate change and sustainable ethical sourcing.

LATEST NEWS

Vitaco Launches ATHENA Sports Nutrition

Vitaco is proud to launch ATHENA, a new sports nutrition brand dedicated to athletic women. Featuring protein powders, supplements and bars, the Informed Sport Certifi…

Australia’s #1 Selling Gut Health Powder Even Tastier

Nutra-Life is excited to expand our Gut Relief powder, the #1 best selling gut health powder in Australian pharmacies*, with a brand new Berry flavour …

Our Vitaco Vibe 2022

Our annual Vitaco Voice survey results, across all our ANZ salaried team members, are in – what a booming result! 90% participation means we are …